Speed Monitoring

Introduction

IRD Mechanalysis Limited as a part of its Condition Monitoring Solutions - offers Solutions for Speed Measurement, Monitoring, Transmission and Protection.

Speed Measurement requires a Toothed Wheel or a Notch on the Rotating Shaft. An Eddy Current Based Non-Contact type Proximity Sensor is used to detect Pulses each time the Toothed Wheel or Notch passes the Sensor Tip. Our Measurement Circuitry counts the number of Pulses in a Second and arrives at the Speed of the Machine in terms of Rotations per Minute (RPM) or Hertz (Hz).

We provide Speed Monitoring in 2 Options:

- Monitoring Circuit mounted near the Machine in an IP65 rated enclosure

- Monitoring Circuit mounted in a Rack in the Control Room in a protected environment

- Provide Instantaneous Speed Display

- Provide 4-20 mA Output for integrating with DCS/PLC/SCADA

- Provide Relay Contacts for Protection and Annunciation

Elements of a Speed Monitoring System

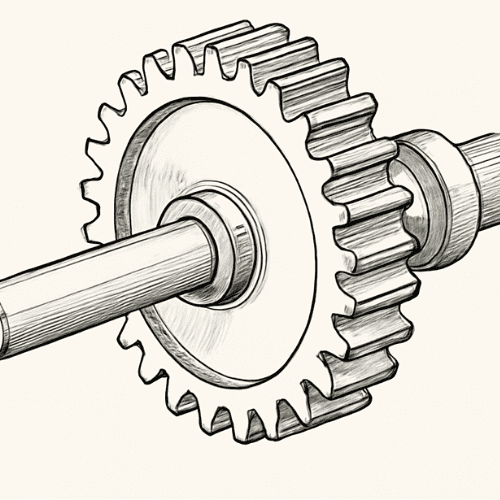

Notch or Toothed Wheel

Speed Monitoring requires a Notch or Toothed Wheel on the Rotating Shaft. This notch or toothed wheel provides the required Pulse Count to the Speed Monitoring Circuit to derive Speed in RPM or Hz. Laser Tachometers can work without Notch or Toothed Wheel using a Reflective patch painted onto the Rotating Shaft. But for Continuous Monitoring - Notch or Toothed Wheel is recommended by us.

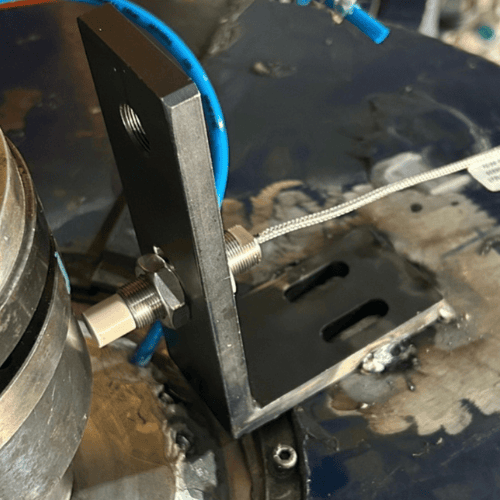

Bracket for Sensor Mounting

To hold the Non-Contact Eddy Current based Sensor in place - a Bracket is needed. The bracket should ensure that Sensor is held firmly in place during Monitoring. We help design Brackets as per Site requirements and Dimensional Constraints. Brackets can be made for Laser Tachometers also - but Laser Tachometers are typically used for one-off measurement and not continuous monitoring and thus Magnetic Mounts are used for them.

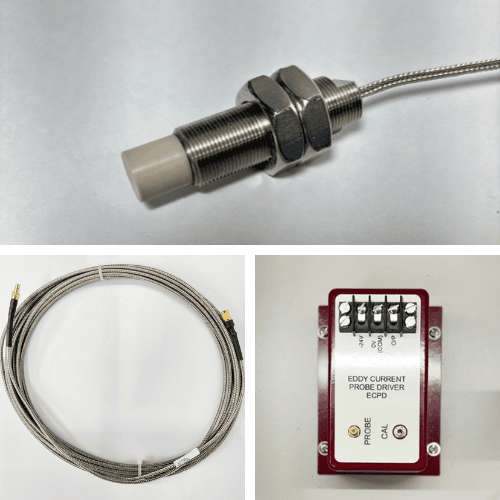

Non-Contact Sensor

Eddy Current Based Non-Contact Sensors are used for Speed Monitoring. Laser Tachometers can also be used - but they are better for Temporary Monitoring rather than Permanent Monitoring. The change in Gap due to a Notch or Toothed Wheel gives rise to a Pulse. These Pulses are transmitted to a Monitoring Circuit which counts them and thereby computes speed in either Hertz (Hz) or Rotations per Minute (RPM)

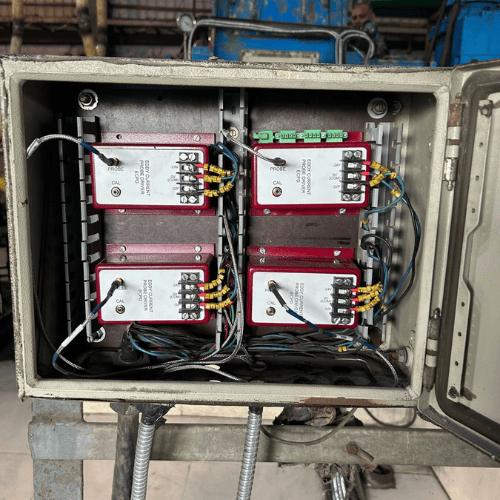

Junction Box

The Non-Contact Eddy Current Based Speed Sensor has a Driver that needs to be mounted within a Junction Box for ease of Power, Input and Output Terminations. We provide Junction Box of varying MOC ranging from FRP, Polycarbonate, Al Die Cast, Explosion Proof and more. We can provide JB with the required Ingress Protection - be it IP54 or IP65 or better. We provide the JB with suitable number of Terminals, Ducts, Input and Output Glands.

Speed Monitoring System

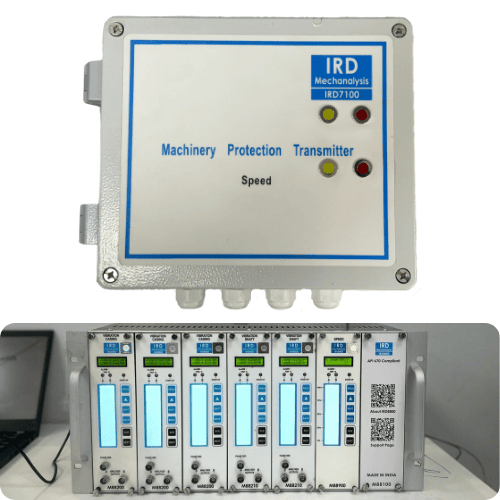

To Continuously Monitor Speed - we provide Monitoring and Protection Systems that can be Wall-Mounted (IRD7100 Series) or Rack Mounted (IRD8800) Series. Both Systems can accept either Non-Contact Eddy Current Sensor Input or Laser Tachometer Input. Both Systems provide per Channel - 4-20 mA Output, Configurable Alarm and Trip Relay Contacts, MODBUS RTU Output. Both Systems can work Round-The-Clock

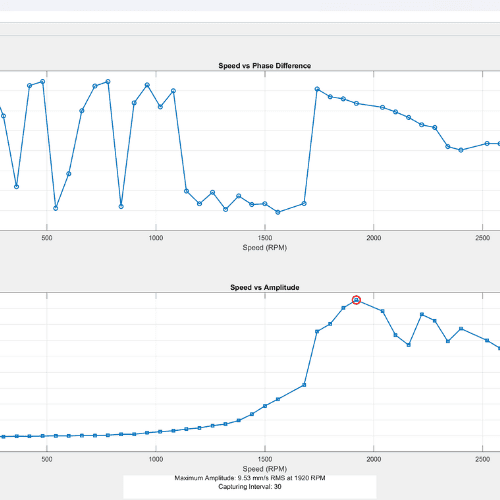

Software for Analysis

We create Software for Vibration, Temperature, Speed, Gap and Turbine Monitoring on our own. We call it OLIVER™. It can be used to Monitor and Analyse the RPM of a Machine. Behaviour such as Change in Vibration with Speed OR Change in Vibration Phase with Speed can be studied in a Bode Plot. Speed Information can be used for Order Tracking and Harmonic Analysis of Vibration Spectrum. Holistic Decisions can be taken by User

Feel free to reach out to us to get a techno-commercial proposal for a Speed Monitoring Solution for your Machinery. We shall be happy to help. We are available on call Monday to Saturday 9:00 AM to 6:00 PM IST on +91-2248972000 and are just an email away at sales@irdmech.com