IRD7100 Series - Machinery Protection Transmitter

Made in India | 5 Years Warranty | Round the Clock Monitoring & Protection

About the Product

IRD7100 Series of Machinery Protection Transmitters (MPT) are designed for use in Harsh and Dusty Industrial Environments. These transmitters can provide 24x7 round the clock monitoring, transmission and protection from ill effects of high vibration.

These Transmitters are Made in India and Made for the World by us at our Factory in Thane, Maharashtra. After-Sales Service in the terms of Warranty and post Warranty Support is available from our Service Center in Thane, Maharashtra.

Salient Features and Advantages

- Available in Single, Dual and Four Channel Configurations

- Available in Aluminium Die Cast, Polycarbonate and Explosion Proof Enclosures

- Industry Standard 4-20 mA DC output which can be connected to Control Room DCS/PLC/SCADA for Trending

- Industry Standard 0-5 V DC Output which can be connected to an External Display

- IP65 rated enclosures and thus Transmitter can be mounted very close the machine - thereby reducing cable costs

- Alarm and Trip Relay for protection from High and Very High Vibration

Optional Outputs

- Buffered Time Waveform Output via BNC that helps connect Portable Data Collectors and Vibration Analyzers to the Field Sensor without need of placement of additional sensor at same position.

- This buffered output can also be provided to an Online Diagnostic System for Advanced Vibration Analysis and Diagnostics

- MODBUS RTU Output for communication with DCS/PLC/SCADA and advanced trending

IRD7100 for Vibration Monitoring

IRD7100 Machinery Protection Transmitter (MPT) is great for Vibration Monitoring. It can be Factory configured to work with Contact Type Vibration Sensors or Non-Contact Type Vibration Sensors. The User gets Live and Large Display at front which is visible from a Distance in Bright Sunlight or at Night. The User also gets 4-20 mA output which can be connected to DCS/PLC/SCADA/Cloud. To Protect the Machine being Monitored - IRD7100 MPT is also equipped with 2 Sets of Alarm Relay Contacts and 2 Sets of Trip Relay Contacts per Channel - these can be used for Tripping as well as Annunciation. We will be happy to help you select the right IRD7100 Vibration Transmitter for your requirement - please write to us at sales@irdmech.com with your requirements

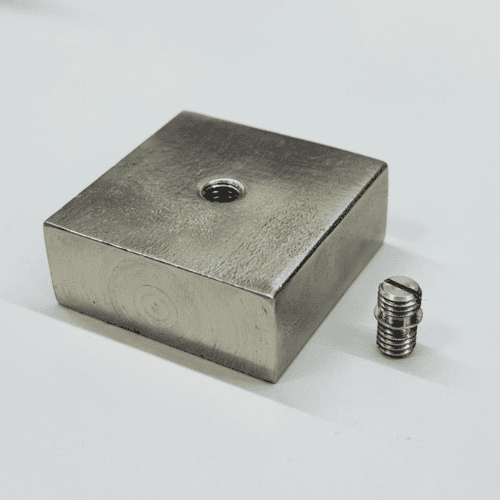

Sensor Mounting Accessories

There is a saying - 'Garbage In - Garbage Out'. Going by that saying - it is important in Vibration Monitoring that the right Sensor and the right mounting accessories for the Sensor are used. We provide and help choose the right mounting accessory for Vibration Sensors - be it Mounting Pads, Studs, Brackets, Magnets or Stands. Our team assesses the dimensional constraints and chooses the best fit for the requirement

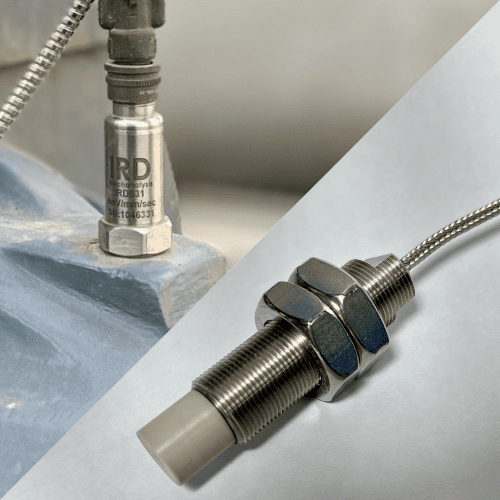

Vibration Sensor

Vibration Sensor is the Heart of the Monitoring System. Several factors affect the choice of the right sensor - be it an Accelerometer (mV/g) or Velometer (mV/mm/sec) or Non-Contact Eddy Current Pickup (mV/um). Our team assesses the requirements and helps pick the right Vibration Sensor for the application. Dimension constraints, temperature conditions, Ingress Protection requirements - everything is considered by us

Interconnection Cables

The Cable between Sensor and Junction Box OR Sensor and IRD7100 Transmitter is made and supplied by us. It can be chosen with Teflon, LHLS or FRLS as the main cable with SS, GI or PVC conduit for Protection. These cables are low-noise and shielded and ensure no loss of signal or inaccuracy in measurement. Cables can be made of the desired length as per Project requirements - with 10 meters being a popular choice

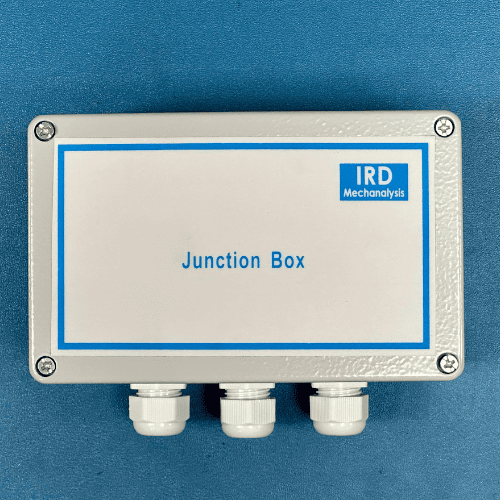

Junction Boxes

In cases where IRD7100 Transmitter is to be mounted at a Central Location rather than near the Machine - it is advised to have a Junction Box near the Machine. This Junction Box helps in termination of connections or acts as a mounting place of Non-Contact Eddy Current Sensor Driver Unit. We provide Junction Boxes in different MOC like SS, MS, CRCA, FRP, Polycarbonate, Explosion Proof and more - complete with Glands

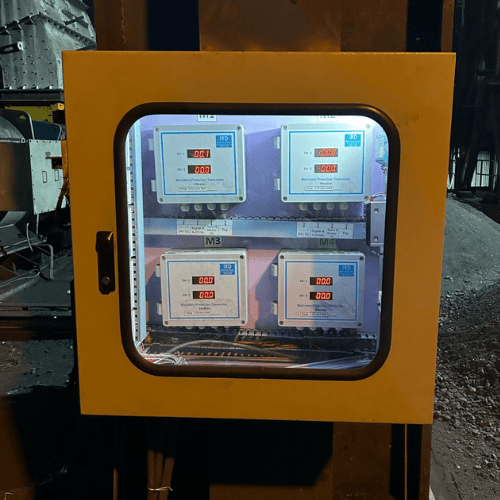

Cabinets

In cases where IRD7100 Transmitter is to be mounted at a Central Location rather than near the Machine - we can provide a Free Standing or Wall Mounted Cabinet to enclose the IRD7100 Transmitter. Please note that by design - IRD7100 can also be mounted in Field near the Machine without need of a Cabinet. If we are asked to provide a Cabinet - we ensure that the Cabinet comes pre-wired for Power, Input & Output

Data Viewing & Analysis

We can provide Software for Data Viewing, Trending and Analysis (We call it Oliver™). Our Monitoring System can also be integrated to DCS/PLC/SCADA/Cloud via 4-20 mA, MODBUS or MQTT. These insights help take Data driven Decisions and carry out Predictive Maintenance. Oliver™ is able to provide Plots such as Waveforms, Spectrums, Trends, Orbit Plots, Bode Plots and more to aid in Analysis

Data Sheets

| IRD7100 for Casing Vibration Monitoring using IRD544M Inductive Velocity Sensor | View Data Sheet |

| IRD7100 MPT for Vibration Monitoring in 280 x 230 x 110 mm Enclosure | View Data Sheet |

User Manual and Connection Diagrams

| User Manual of IRD7100 MPT for Vibration Monitoring | Access User Manual |

| Connection Diagram for 2 Channel IRD7100 MPT with Accelerometer IRD521 100 mV/g | View Connection Diagram |

Commissioning Support

If you need assistance in Commissioning of your IRD7100 Transmitter - then you can call us on +91-2248972000 (Monday to Saturday 9 AM to 6 PM IST) or email us on service@irdmech.com for scheduling Service Support by a Trained and Qualified Service Engineer

Repairs and Calibration

If you need Repair or Calibration for your IRD7100 Vibration Transmitter or its Sensor - then please call us on +91-2248972000 (Monday to Saturday 9 AM to 6 PM IST) to schedule an appointment or discuss Logistics. Alternatively - you can email us on service@irdmech.com to schedule your request with us.

Find a Distributor near you

IRD7100 MPT for Temperature Monitoring

IRD7100 MPT can be factory ordered for Temperature Monitoring using RTD PT100 Sensor. Salient points of IRD7100 MPT for Temperature Monitoring are:

- The Sensor could be a dedicated RTD PT100 Sensor or a Dual Output Vibration cum Temperature Sensor.

- The IRD7100 Transmitter can be ordered to be Single Channel, Dual Channel or Four Channel in a variety of Enclosure Options - Al Die Cast, CRCA, Polycarbonate, Explosion Proof and more.

- IRD7100 MPT will provide Live Display of Temperature, provide 4-20 mA output proportional to Full Scale and provide Alarm as well as Trip Relay Contacts per Channel that can be used for Machinery Protection

IRD7100 MPT for Gap Monitoring

IRD7100 MPT can be factory ordered for Gap Monitoring using Non-Contact Eddy Current based Sensor. Salient points of IRD7100 MPT for Gap Monitoring are:

- The Sensor could be used to Sense Air Gap or Radial Gap or Axial Gap - based on the orientation of the Sensor.

- The IRD7100 Transmitter can be ordered to be Single Channel, Dual Channel or Four Channel in a variety of Enclosure Options - Al Die Cast, CRCA, Polycarbonate, Explosion Proof and more.

- IRD7100 MPT will provide Live Display of Gap, provide 4-20 mA output proportional to Full Scale and provide Alarm as well as Trip Relay Contacts per Channel that can be used for Machinery Protection

IRD7100 MPT for Speed Monitoring

IRD7100 MPT can be factory ordered for Speed Monitoring using Non-Contact Eddy Current based Sensor. Salient points of IRD7100 MPT for Speed Monitoring are:

- The Sensor needs a Notch on the Target surface or a Toothed Wheel for counting Pulses per Second and to derive Speed.

- The IRD7100 Transmitter can be ordered to be Single Channel, Dual Channel or Four Channel in a variety of Enclosure Options - Al Die Cast, CRCA, Polycarbonate, Explosion Proof and more.

- IRD7100 MPT will provide Live Display of Speed, provide 4-20 mA output proportional to Full Scale and provide Alarm as well as Trip Relay Contacts per Channel that can be used for Machinery Protection

IRD7100 MPT for Bearing Monitoring

IRD7100 MPT can be factory ordered for Bearing Monitoring using Casing Vibration Accelerometer 100mV/g Sensor. Salient points of IRD7100 MPT for Bearing Monitoring are:

- The Sensor will be used to measure Spike Energy - a Trademark parameter of IRD Mechanalysis Limited that tells Condition of Rolling Element Bearings (Anti-Friction Bearings).

- The IRD7100 Transmitter can be ordered to be Single Channel, Dual Channel or Four Channel in a variety of Enclosure Options - Al Die Cast, CRCA, Polycarbonate, Explosion Proof and more.

- IRD7100 MPT will provide Live Display of Spike Energy in gSE and provide 4-20 mA output proportional to Full Scale

IRD7100 for Turbine Monitoring

IRD7100 MPT can be factory ordered for Turbine Monitoring. Salient points of IRD7100 MPT for Turbine Monitoring are:

- Parameters such as Rotor Eccentricity, Differential Expansion, Casing Expansion (Shell Expansion), Turbine RPM, Turbine Vibration and More can be Monitored.

- The IRD7100 Transmitter can be ordered to be Single Channel, Dual Channel or Four Channel in a variety of Enclosure Options - Al Die Cast, CRCA, Polycarbonate, Explosion Proof and more.

- IRD7100 MPT will provide Live Display of Parameters, provide 4-20 mA output proportional to Full Scale and provide Alarm as well as Trip Relay Contacts per Channel that can be used for Machinery Protection

Enclosure Options for IRD7100 MPT

IRD7100 MPT can be ordered in Enclosure of your choice - be it FRP, CRCA, MS, SS or others. Some common and popular options are shown below

Aluminium Die Cast

It is the most common and popular option for IRD7100 MPT because it allows housing of Electronics whilst ensuring Good Ingress Protection (IP65). The Hinged Door facilitates Access to Internals of the Housing.

For 2 Channels the dimension will be 230 x 200 x 110 mm or 280 x 230 x 110 mm.

The Enclosure can be Wall Mounted onto any Support Structure - be it a Fabricated Stand or Wall or Cabinet Mounting Plate

Polycarbonate

For 2 Channels the dimension will be 300 x 300 x 170 mm. For 4 Channels the dimension will be 600 x 300 x 170 mm

The Enclosure can be Wall Mounted onto any Support Structure - be it a Fabricated Stand or Wall or Cabinet Mounting Plate