Vibration Measurement and Analysis

Principles and Concerns

There are some fundamental principles that apply to all rotating machinery. They are:

- All Machines Vibrate when they run

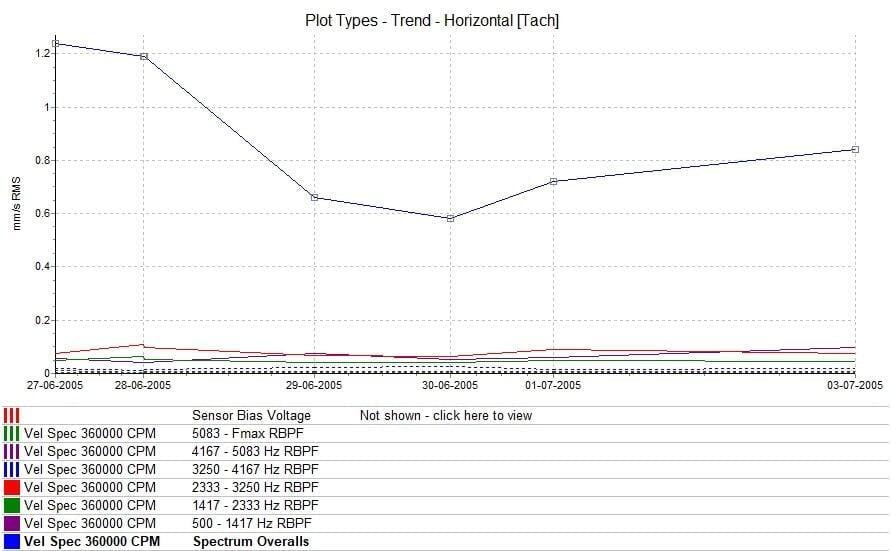

- Any increase in Vibration is a sign of trouble

- Each trouble has its own unique characteristics

These Characteristics are Amplitude, Frequency and Phase. Each Characteristic has its own significance:

- Amplitude - Indicates Severity of Vibration

- Frequency - Indicates most likely cause of Vibration

- Phase - Helps Identify exact cause of Vibration

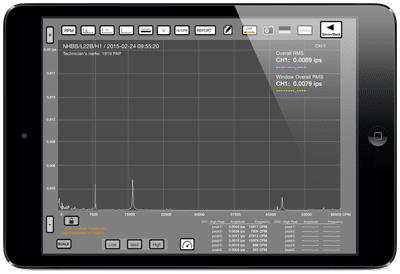

While Understanding Vibration Amplitude is pretty simple and Straight Forward; Understanding Vibration Frequency and Vibration Phase is not so. Many a times, it is found that people own the right tools to measure vibration amplitude, frequency and phase, but are either unable to use the tools to their full potential and are therefore in need of assistance in using the tools to their full potential

How do we help?

We have a team of trained engineers, experts, technicians equipped with the right tools. They can help you carry out Vibration Measurement and Analysis. They can help you understand the following:

- Which of your Rotary Equipment are in Good Health and which of them need attention? We do this by comparing observed vibration levels with Severity Charts such as ISO 2372 or ISO 10816

- What is the underlying cause of high vibration in the equipment needing attention? Problems that can be detected are:

- Unbalance

- Looseness

- Misalignment

- Resonance

- Electrical Faults

- Several Others

- What is the recommended action to be carried out to bring down the Vibration to acceptable levels? We can also help carry out the recommended action such as:

- In-Situ Dynamic Balancing of Rotor

- Laser Alignment across Coupling

- Suggest Design Changes in event of Resonance